At present, there are two main types of materials used to make POF: one is PMMA (Polymer Polymethylmethacrylate); the other is Perfluorinated polymers.

Plastic optical fibercan not only be used in the last 100-1000 meters of the access network, but also can be used in various vehicles, aircrafts, and other means of transportation.

Plastic optical fiber(POF) is made of highly transparent polymers such as polystyrene (PS), polymethyl methacrylate (PMMA), and polycarbonate (PC). Optical fiber (optical fiber). Different materials have different light attenuation properties and temperature application ranges. The main performance indicators are:

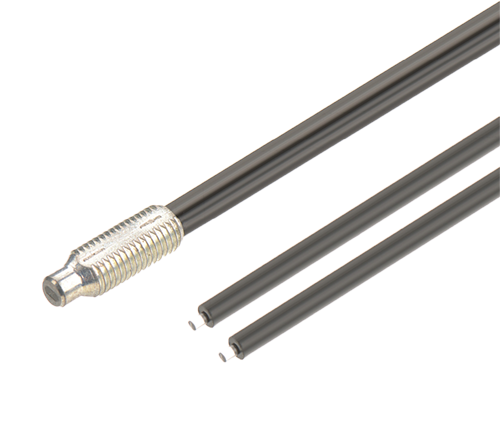

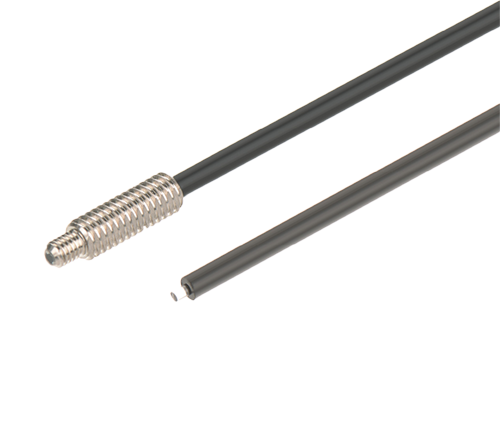

STRUCTURE OF PLASTICAL OPTIC FIBER

Picture Source :Google

The attenuation of plastic optical fiber mainly depends on the scattering loss and absorption loss of the selected material. To be a communication-grade plastic optical fiber, one of the most basic requirements is that the attenuation of PMMA plastic optical fiber is low, preferably less than 180dB / km.

Gradient plastic optical fibers are optical fibers with a gradient distribution of refractive index, whose refractive index gradually decreases from the core to the cladding. As long as the formed gradient refractive index profile is appropriate, the effects of suppressing modal dispersion, maintaining a large data aperture, and controlling the broadening of outgoing light waves relative to human light waves can be obtained. If the refractive index distribution is proper, the material dispersion becomes the main factor that determines the transmission bandwidth. As long as full attention is paid to the material dispersion in the selection, it is completely feasible to obtain a bandwidth of several Ghz • km.

Most importantly, the heat resistance of plastic optical fiber is mainly determined by its component properties. The material composition with good heat resistance determines that the plastic optical fiber has relatively good heat resistance. The indicators for judging the heat resistance of materials include glass transition temperature, Vicat softening point, and thermal deformation temperature.

Picture Source :360 Website

Communication plastic optical fiber mostly uses 1mm diameter optical fiber, which is 8-20 times of quartz optical fiber. The connection of thick plastic fiber is much easier than that of quartz fiber.

Plastic optical fibers are lightweight, flexible, and more resistant to damage (vibration and bending). Plastic optical fiber has excellent tensile strength, durability and small footprint. These advantages make the successful application of plastic optical fiber particularly important in automobiles. The interior of a typical luxury car consists of at least a few kilometers of copper wires and cables, which greatly increase weight and cost. This is true of planes, trains and all other means of transportation.

Due to the large diameter and numerical aperture of the plastic optical fiber, the light transmission capacity is large. Plastic optical fibers have much higher bandwidth capabilities than copper-based transmission media (twisted pair and coaxial cables). The higher the transmission frequency, the lower the cost of using plastic optical fiber.

Cutting, routing, bonding, polishing, and other processing of plastic optical fibers is easy. Due to the large diameter, the installation and connection of plastic optical fibers with devices, light sources, detectors, etc. becomes easy and low-cost, and non-professionals can perform these operations. Prepare the connection of plastic optical fiber in less than 1 minute, and no special tools are required. Even the simplest scissors can be used to cut plastic fibers. The plastic optical fiber transceiver module uses red light with a wavelength of 650nm, which is very safe. Users can easily see whether the optical fiber connection is successful. In addition, the connection of the plastic optical fiber is insensitive to dust and debris hidden on the end surface.

Plastic fiber cable does not generate radiation and is completely immune to electromagnetic interference, radio frequency interference, and noise. This is especially important for the streaming of video and audio. Obviously, these interferences and noises affect the quality of images and services. Plastic optical fibers can be laid side by side with copper cables in the same duct or in the same wiring harness. Plastic optical fiber does not generate noise and will not adversely affect the current pipe network.

Data transmission through plastic optical fiber is not likely to be eavesdropped, so plastic optical fiber is very suitable in some places with high security requirements.

Related Products

Related Products

View More(Total0)Comment Lists